SMART Flexible Innovation Support.

SMART FIS is a unique Welsh Government Scheme with the single aim of helping Welsh organisations achieve “Innovation Excellence”.

Welsh Government.

Delivered by a team of specialists – engineering, science, industry and intellectual property. SMART FIS is open to any organisation wishing to engage in research, development and innovation (RD&I), including businesses, the third sector, public sector bodies, academic institutions and research organisations. Typical value of the funding on offer is £100k over a 2 year period at a 50% intervention rate for research, development and exploitation of innovation; product, process and service innovation; as well as embedding culture of skills, growth and citizen benefit.

When applying for support, an Innovation Plan will need to be supplied. This should include: short, medium and long-term innovation goals/impact; circular economy activities related to product, process, and organisation innovation; gaps in capability and capacity; and relevant partners in a collaborative project with an explanation of how risk and reward will be shared. Welsh Government aim to make a funding decision within 20 working days, dependent on size and complexity of the Innovation Plan.

Express Interest.

SMART Productivity & Design.

We are the nominated design and manufacturing partner who support Welsh Government in the delivery of their SMART Productivity and Design programme.

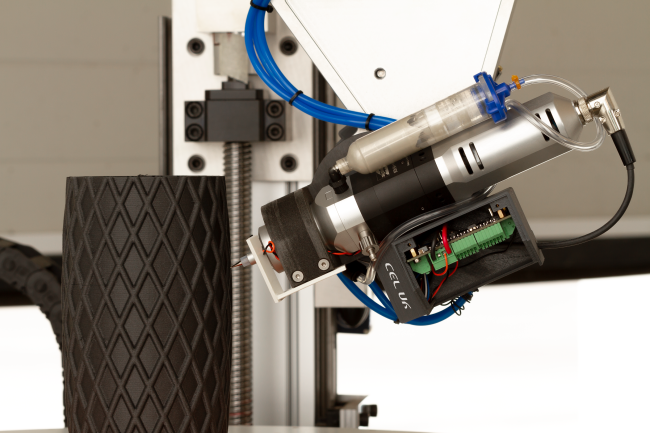

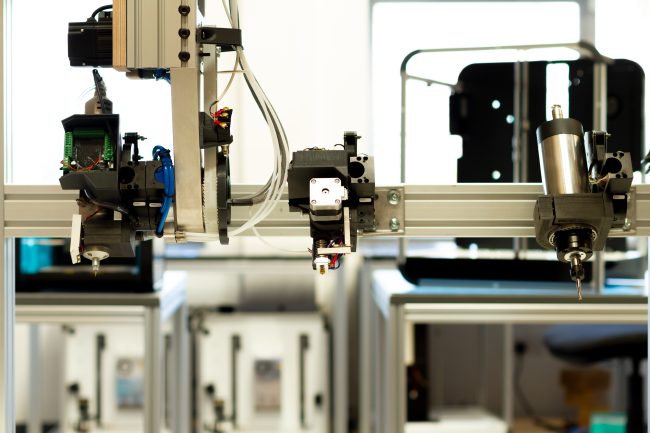

The scheme offers Welsh SMEs the opportunity to access fully funded consultancy within the field of design and manufacturing for up to 8 days, which is delivered in two phases: diagnostic (3 days) and implementation (5 days). The ultimate aim of the SMART scheme is to stimulate economic growth and job creation in Wales through: the development of new products; the introduction of more productive manufacturing processes; and the creation of novel intellectual property.

Our team of specialist consultants have expertise in: Design Process Improvement, Product Research, Competitor Analysis, Conceptual Design, Engineering Design, Rapid Prototyping, CE Marking, Six Sigma, Lean Manufacturing, 5S, Value Stream Mapping, Process Improvement, Waste Reduction and Industry 4.0.

SMART Productivity & Design has supported a vast number of Welsh SMEs across a broad range of sectors. In order to qualify for such Welsh Government funding and associated Welsh Government business grants, the organisation must be located within Wales and ideally employ 10+ members of the staff.